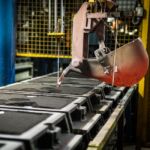

La nostra produzione viene eseguita da due linee di formatura automatiche con colata robotizzata, dotate delle seguenti misure di staffa:

– 460 x 520 h 175+175

– 600 x 800 h 285+285

Vengono servite da un impianto automatizzato per la preparazione delle terre gestito da PLC dotato di controllo continuo dell’umidità e della compattazione.

Disponiamo di un forno fusorio rovesciabile e 5 forni di attesa di varie capacità nei quali, prima della colata, vengono eseguiti trattamenti di scorifica, degasaggio, affinazione e modifica del metallo fuso.

Le principali leghe da noi utilizzate sono :

EN AB 42000 (AlSi7MgTi)

EN AB 42100 (AlSi7Mg0,3)

EN AB 43100 (AlSi10Mg)

EN AB 44100 (AlSi12)

EN AB 46400 (AlSi9Cu1)

EN AB 71100 (AlZn10Si8)

Eventuali altre leghe possono essere impiegate su richiesta del cliente.